Discover how foundation bolt exporters broaden construction horizons. Their expertise and quality products elevate structural stability, ensuring a solid foundation for diverse building projects.

Imagine towering skylines that pierce clouds, sprawling bridges connecting continents far and wide, and wind turbines harnessing nature’s winds across diverse terrains. Each marvel of modern engineering shares an unseen yet crucial companion: foundation bolts. These anchors form the bedrock beneath global construction, steadying structures and ensuring stability amid ever-changing conditions.

However, navigating the realm of foundation bolt suppliers from abroad can feel daunting, especially when straying beyond domestic borders. Enter foundation bolt exporters – your portal to varied solutions and unrivaled know-how, broadening your construction horizons more than ever before.

Beyond Boundaries: Embracing Global Opportunity

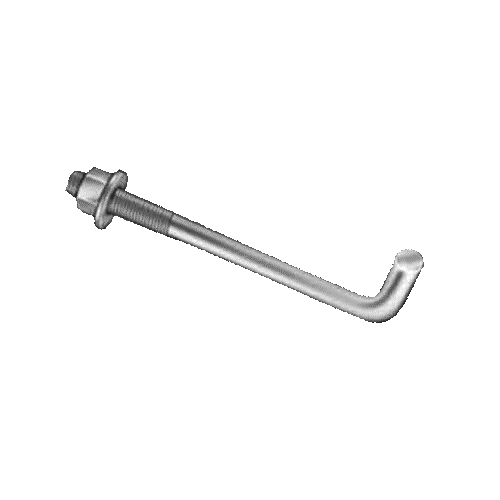

Opting for a foundation bolt exporter presents several compelling benefits: Access to a vast assortment of bolts tailored to unique project needs, from standard J-bolts to custom anchors meeting international codes worldwide. Exporters bridge gaps between requirements and globally accessible options. Leverage economies of scale and potentially lower costs through manufacturers across regions. This can optimize budgets while maximizing value for any venture.

Advanced Technologies: Gain access to cutting-edge manufacturing processes and innovative bolt designs pioneered by international heavyweights. This ensures your venture capitalizes on material science’s latest advancements.

Specialized Expertise: Tap diverse construction practices’ accumulated knowledge and experience from international teams focused on varied environments. This expertise nurtures disruptive thinking and provides valuable perspectives for your project.

Navigating the Globalized Landscape in Search of the Ideal Export Partner:

With worldwide markets now within reach, carefully consider each potential foundation bolt exporter. Here are factors guiding the selection:

Reputations and proven accomplishments — seek proven exporters delivering quality, dependability, and success on international ventures.

Portfolio adaptability — ensure customizable bolt types, dimensions, and materials for your undertaking’s exacting needs and worldwide benchmarks.

Compliance confirmation and qualifications — verify adherence to applicable international standards and industry validation, guaranteeing attributes meeting regulatory mandates.

Logistical and delivery deftness — prioritize exporters proven at international shipment handling and adept at navigating potential import/export intricacies.

Communication and support prioritization — choose an exporter valuing lucid conversing, providing multilingual assistance, and availability to address all queries and issues throughout.

Building Bridges, Cultivating Trust:

Remember, partnering with an international supplier exceeds a transaction. Constructing confidence and nurturing teamwork are crucial to achieving success. Here are methods to cultivate a powerful working relationship:

Clearly convey your project particulars: Provide exact specifications, schedules, and any unique needs to guarantee the exporter fully grasps your vision.

Collaborate on technical facets: Actively engage with the exporter’s engineers to investigate optimal remedies, material selections, and potential obstacles depending on the undertaking’s exclusive setting.

Preserve open interaction: Establish clear communication routes and maintain consistent contact throughout, addressing any matters promptly.

Embrace cultural variances: Be watchful of and respect cultural nuances besides styles of interaction to facilitate a smooth in addition collaborative partnership.

Beyond Boundaries, Beyond Expectations:

By collaborating with foundation bolt exporters, you unlock a realm of possibilities:

Building in Diverse Environments: Source bolts specially designed for challenging environments like coastal areas, earthquake zones, or extreme temperatures, confirming optimal performance regardless of location.

Embracing Sustainable Practices: Access eco-friendly bolt solutions like those made from recycled steel or bio-composites, aligning your project with global sustainability goals.

Leveraging Cutting-Edge Technology: Integrate smart bolts embedded with sensors into infrastructure, enabling live monitoring and proactive servicing for boosted safety and productivity.

The Future of Global Cooperation:

The destiny of base anchorage exports is one of constant betterment and teamwork. Imagine: Novel materials: Employing groundbreaking substances like carbon fiber or graphene hybrids to build lighter, stronger, and more eco-friendly anchors. Digitization: Incorporating blockchain tech for heightened supply chain visibility and traceability, confirming principled sourcing and quality oversight. Global teamwork: Cultivating closer relations between international research hubs, producers, and construction firms to share knowledge and push design and output restrictions. By collaborating with relied on base anchorage exporters, you become part of this ever-evolving landscape, adding to the engineering of a greener, more capable, and interconnected world. Remember, base anchors may be small, but their impact is global, connecting nations, cultures, and dreams through the shared foundation of quality, collaboration, and innovation.

From Urban Skylines to Oceanic Wind Farms: Real-World Examples:

To illustrate the effect of base anchorage exporters, let’s delve into motivating case reports: Case Study 1: Scaling Fresh Peaks in Dubai Project: Burj Khalifa, the world’s loftiest skyscraper.

Case Studies: Tackling Testing Terrain with Technical Transport

Project 1: Constructing the Colossal in a Climate of Calefaction

Task: Securing sturdy stabilization stanchions to shelter a sky-high sentinel from scorching sands surrounding Dubai.

Solution: A German fixture fabricator fused forefront formulas and specialized coatings, ensuring utmost fortitude facing foreseen forces.

Result: The Burj Khalifa stands stalwart, a testament to international collaboration and innovative solutions sourced.

Project 2: Harnessing Breezes Beyond Briny Borders

Goal: Erecting a extensive expanse of wind turbines withstanding wear in wet waters of the North Sea.

Provision: A proficient Dutch provider particularly prepared protectively plated posts capable of carrying mammoth machinery.

Result: Power is produced pollution-free, proving partnerships prevail for perplexing placements.

Project 3: Reconstructing Have Following Havoc

Mission: Mending mangled municipalities necessitating naturally non-disastrous foundations for facilities following earthquakes.

Hurdle: Locating a liable exporter able to deliver quality anchors quickly to quicken recovery.

Solution: A South Korean foundation bolt exporter with experience in disaster relief zones stepped in, offering expedited production and delivery of certified earthquake-resistant bolts, enabling communities to rebuild more quickly.

Result: Through global partnerships like this one, communities were rebuilt faster and safer, demonstrating the positive humanitarian impact possible when international players collaborate in times of crisis.

Beyond Borders, Beyond Expectations:

These case studies showcase the diverse applications and significant humanitarian impact of foundation bolt exports. From iconic landmark reconstruction to sustainable energy projects aiding recovery, these international partnerships push the boundaries of innovation and contribute to a better future for all.

The Road Ahead: A Collaborative Future:

As technologies evolve and global challenges change, the need for collaboration between construction firms, engineers, and foundation bolt exporters becomes increasingly important. Imagining a future with joint research accelerating new sustainable, high-performance bolt solutions and streamlined international standards easing cross-border trade ensures consistent quality worldwide. Knowledge exchange empowering local expertise through capacity building from developed to developing nations can help drive global infrastructure development.

By embracing collaborative pathways, we can fully unleash innovation’s potential via foundation bolt exports, building a future defined by cooperation, sustainability, and shared knowledge—paving the way for a more connected and resilient world.

Imagine emerging amid sweltering flames, molded by pressure, destined to fortify towering constructs. This anonymous guardian’s journey:

From Molten Cradle to Enduring Might:

Our tale starts in a steel mill’s heart, where as incandescent liquid I existed at 3000°F. Skillful technicans guided my formation, ensuring optimal balance of resilience and flexibility via temperature mastery and alloy nuance.

Next, into the forging dance’s fiery choreography I was thrust. Sturdy machines pummeled relentlessly, shaping raw potential into a J-bolt built to anchor wood into concrete. Under immense compression, born resilient, prepared to withstand colossal stresses.

The Tempering Transformation: Refining Strength through Heat

Mere tensile might alone cannot suffice. I now journey into the realm of tempering, where precise temperature regulation and tailored quenches sculpt my innards. This alchemical refinement enhances my internal constitution, granting an ideal harmony of tensile toughness to withstand immense pulling powers and malleability to adjust to fluctuating conditions.

The Threading Technique: Precision Shapes through CNC

The moment of meticulous machining has arrived. CNC machinery, steered by practiced hands, carve indentations onto my form with micron-level nicety. Each groove fits flawlessly, ensuring a smooth and secure joining with opposing parts. Such diligent attention to nuance confirms unfailing functionality in any undertaking.

Read Also: Unsung Heroes: Acknowledging Hex Bolt Manufacturers in Construction

Testing to Prove Exceptional Mettle

No piece leaves the works unfinished without exhaustive testing. Non-intrusive evaluation like ultrasonic or magnetic flecking scan for concealed flaws, confirming I am free from blemishes. Then comes the grand finale – load testing. I am subjected to simulated real situations, surpassing intended thresholds, proving I can handle the most taxing scenarios. This relentless pursuit of quality guarantees outstanding performance.

From Assembly Line to Job Site: Embracing My Intended Use:

My journey continues as I’m hauled off, transported to boisterous build sites around the globe. Here, I am enthusiastically received by experienced artisans who recognize my indispensable role. They carefully emplace me, anchoring wooden structures to cement footings, forming the hidden skeleton of dreams taking shape.

A Legacy of Stability through the Years:

Decades pass, and the framework I steady stands resilient, enduring storms and facing hardships. I linger out of sight, silently working to guarantee security and safety. The weight of the construction above rests on my shoulders, a duty I bear with unwavering might.

Beyond Steel: A Symbol of Human Ingenuity’s Triumph:

Though just a simple piece of metal, I exemplify the accumulation of human inventiveness, meticulous crafting, and relentless pursuit of quality. From lofty skyscrapers to intricate bridges, I play a vital part in shaping the world around us.

FAQs about Foundation Fasteners: Your Guide to Invisible Strength

What exactly are foundation bolts utilized for?

Foundation bolts come in various forms, each uniquely suited to serve specific construction needs. J-bolts anchor wood structures, while L-bolts handle horizontal stresses. Wedge anchors expertly retrofit aging infrastructures. High-strength steels like A307 offer noteworthy resilience against even the harshest sites.

However, for coastal regions susceptible to corrosion, stainless steel warrants consideration. In extremely demanding applications, specialized alloys prove fit for purpose. Determining the appropriate bolt attributes requires understanding anticipated load amounts and embedment depths.

Environmental conditions like constant exposure to salty air further influence material selection. Local construction codes also dictate minimum grade specifications. As for threading, course and fine options exist. For a secure, leak-proof joint, ensure thread compatibility with any accompanying nuts or washers to avoid the weakness of cross-threading during assembly.

- What finishes are available, and when are they needed? Galvanization or other coatings protect against corrosion, choosing appropriately based on conditions bolts will face keeps them from degrading. For example, galvanized bolts suitable outdoors, while plain steel might work indoors.

- Are there any extra specifications I should consider? Certainly, as seismic standards, fire resistance ratings, or certifications could be crucial depending on the project. Consult your engineer or supplier to ensure all criteria are met.

- How can I find a trusted foundation bolt provider? Look for companies with a proven track record through successful, quality projects delivered on time. Suppliers should offer various bolt types, sizes, and materials adhering to industry standards and quality management. Technical guidance and assistance from experts can help navigate requirements. Transparent pricing and timely shipping keep costs down and schedules on track.

What’s the difference amid foundation bolts and anchor bolts? Usually used interchangeably, “foundation bolt” refers to bolts fixed directly in concrete, while “anchor bolt” can too designate fasteners close to other building materials.