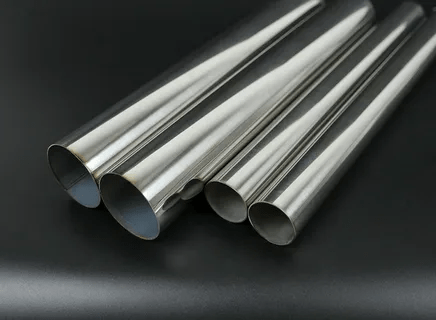

Stainless steel welded pipes – the unsung heroes of the industrial world. These unassuming tubes are pivotal in various industries, from construction to manufacturing and household applications. This comprehensive guide will delve into stainless steel welded pipes, exploring their properties, applications, and why they are a crucial choice in metal piping.

The Foundation: What Are Stainless Steel Welded Pipes?

Stainless steel welded pipes are a type of pipe made from stainless steel sheets. The process involves rolling the sheets into cylindrical shapes and welding them along the seam. This creates a durable and corrosion-resistant pipe suitable for various applications.

The Advantages of Stainless Steel

Stainless steel is renowned for its exceptional properties, making it the material of choice for many industries. Let’s highlight some of the key advantages of stainless steel welded pipes:

1. Corrosion Resistance: Stainless steel pipes are highly corrosion-resistant and ideal for transporting liquids and gases, even in aggressive environments.

2. Strength and Durability: These pipes boast impressive tensile strength, ensuring they can withstand high-pressure applications and extreme temperatures.

3. Hygiene: Stainless steel is non-porous and easy to clean, making it perfect for industries where hygiene is paramount, such as the food and pharmaceutical sectors.

4. Aesthetic Appeal: Beyond functionality, stainless steel pipes offer a sleek and modern appearance, making them popular for architectural and interior design projects.

Stainless Steel Grades: Finding the Perfect Match

steel comes in various grades, each with its unique properties. Choosing the right grade is essential to ensure the optimal performance of your welded pipes. Here are some common stainless steel grades used in welded pipes:

1. 304 Stainless Steel: This is the most commonly used grade for welded pipes. It offers good corrosion resistance and is suitable for various applications.

2. 316 Stainless Steel: Known for its superior corrosion resistance, 316 stainless steel is ideal for applications involving exposure to saltwater or harsh chemicals.

3. 321 Stainless Steel: This grade is highly resistant to high temperatures and is often used in heat applications.

4. 410 Stainless Steel: With excellent wear and abrasion resistance, 410 stainless steel is ideal for applications in the oil and gas industry.

Applications Across Industries

Stainless steel welded pipes find their place in various industries due to their versatility and durability:

- Construction

In the construction industry, stainless steel welded pipes are used for structural support, handrails, and plumbing systems. Their resistance to corrosion and extreme weather conditions make them a reliable choice for indoor and outdoor projects.

- Manufacturing

Manufacturers rely on stainless steel welded pipes for conveying fluids and gases within their production processes. These pipes can handle high-pressure applications while maintaining the purity of the substances being transported.

- Automotive

In the automotive industry, stainless steel welded pipes are used in exhaust systems. Their heat and corrosion resistance ensures these critical components’ longevity and optimal performance.

- Oil and Gas

Oil and gas pipelines demand pipes that can withstand harsh environments. Stainless steel welded pipes, particularly those made from 410 stainless steel, are the go-to choice for these applications.

- Household

Stainless steel pipes are also found in our homes, playing a role in plumbing systems, kitchen appliances, and even decorative fixtures. Their aesthetic appeal and corrosion resistance make them a top choice for homeowners.

Making the Sustainable Choice

In an era where sustainability is a top priority, stainless steel welded pipes stand out as an eco-friendly option. Their long lifespan, recyclability, and minimal maintenance requirements make them an environmentally responsible choice.

Conclusion

- Stainless steel welded pipes are the unsung heroes of various industries, offering unmatched durability, corrosion resistance, and versatility. Whether constructing a building, manufacturing products or enhancing your home, these pipes are reliable. Understanding the different grades and applications empowers you to make informed decisions that transform your projects into long-lasting successes. So, next time you encounter stainless steel welded pipes, you’ll appreciate the remarkable qualities that lie within these unassuming tubes.

In the construction industry, stainless steel welded pipes are used for structural support, handrails, and plumbing systems. Their resistance to corrosion and extreme weather conditions make them a reliable choice for indoor and outdoor projects.