The dependability and effectiveness of Graco sprayers are probably well-known to those who work with painting or coating surfaces. Graco has earned a solid reputation in the market for building high-performance sprayers of the highest caliber. To ensure they continue to perform at their peak, Graco sprayers need routine maintenance. Knowing when and how to repair important parts is an important part of sprayer maintenance. The best replacement components for maintaining and keeping your Graco sprayer in good working order are covered in this article.

Why Regular Upkeep Is Crucial

It’s important to comprehend why routine maintenance is critical for your Graco sprayer before diving into precise replacement parts. Neglecting maintenance can result in several problems. It includes lowered performance, uneven coatings, and expensive downtime. Here are some strong arguments in favor of giving sprayer maintenance priority:

Optimal Performance

Regular maintenance makes sure that your sprayer performs at its best, producing reliable results of the highest caliber.

Robustness

Extending the lifespan of your Graco sprayer by replacing worn-out parts promptly can save you money on repeated replacements or repairs.

Safety

Using a sprayer that has been properly maintained lowers the danger of accidents and injuries brought on by broken or malfunctioning parts.

Cost Savings

Dealing with major repairs or replacements that arise from carelessness is frequently more cost-effective than preventive maintenance.

Spray Nozzles and Tips

Spray tips and nozzles are essential parts of your Graco sprayer that have a direct bearing on the effectiveness and caliber of your work. These components may deteriorate over time, resulting in problems including uneven spraying patterns and more overspray. It’s crucial to frequently inspect and replace these parts as needed to maintain consistent performance. We will discuss Graco sprayer parts.

Replacement Schedule

Spray tips and nozzles may need to be changed every 50 to 100 hours of operation, or earlier if you observe a performance drop, depending on usage.

Filters

Filters are essential for keeping your sprayer free of particles and pollutants. It could clog the system and lower the finish quality. Both the input and output filters on Graco sprayers normally need to be checked and replaced regularly.

Replacement Schedule

Filters should be checked, cleaned, and replaced as needed regularly. Every 50 to 100 hours, replacement may be required in situations with significant usage.

Packing Kit for Pumps

The pump packing kit for your Graco sprayer contains seals and packings that assist in maintaining pressure and preventing leaks. These parts are constantly exposed to high-pressure fluids and chemicals. It can cause them to deteriorate over time.

Replacement Schedule

Every 200–300 hours of operation, or whenever you observe leaks or a pressure drop, you might want to replace the pump packing kit.

Sections that Flow

The coating substance is transferred and pressurized by the fluid section of your Graco sprayer. This area is made up of some wear-and-tear parts, such as diaphragms, balls, and seats.

Replacement Schedule

Fluid section components may need to be replaced every 500 to 1000 hours. This depends on usage and the kind of materials sprayed.

Connectors and Hoses

For the coating material to be delivered from the pump to the spray gun, hoses, and fittings are essential. Due to ongoing bending and chemical exposure, these components are susceptible to deterioration over time.

Schedule for replacement

Regularly check hoses and fittings for wear, cracks, or leaks. If necessary, swap them out, and think about doing so every 200 to 300 hours of use.

Sprayer and Trigger Unit

The instrument you use most frequently when painting or applying coatings is the spray gun. A spray gun that is well-maintained guarantees precise control and lessens strain. Over time, parts like the trigger assembly and gun filters may need to be replaced.

Schedule for replacement

Keep an eye on the state of your spray gun and its parts. To maintain comfort, rapidly replace worn-out components.

Parts for Pressure Control

For maintaining constant pressure levels, pressure control components such as regulators and gauges are crucial. Uneven coatings may be the result of any pressure variations.

Schedule for Replacement

Inspect pressure control components regularly, and replace them if you find pressure variations or incorrect readings.

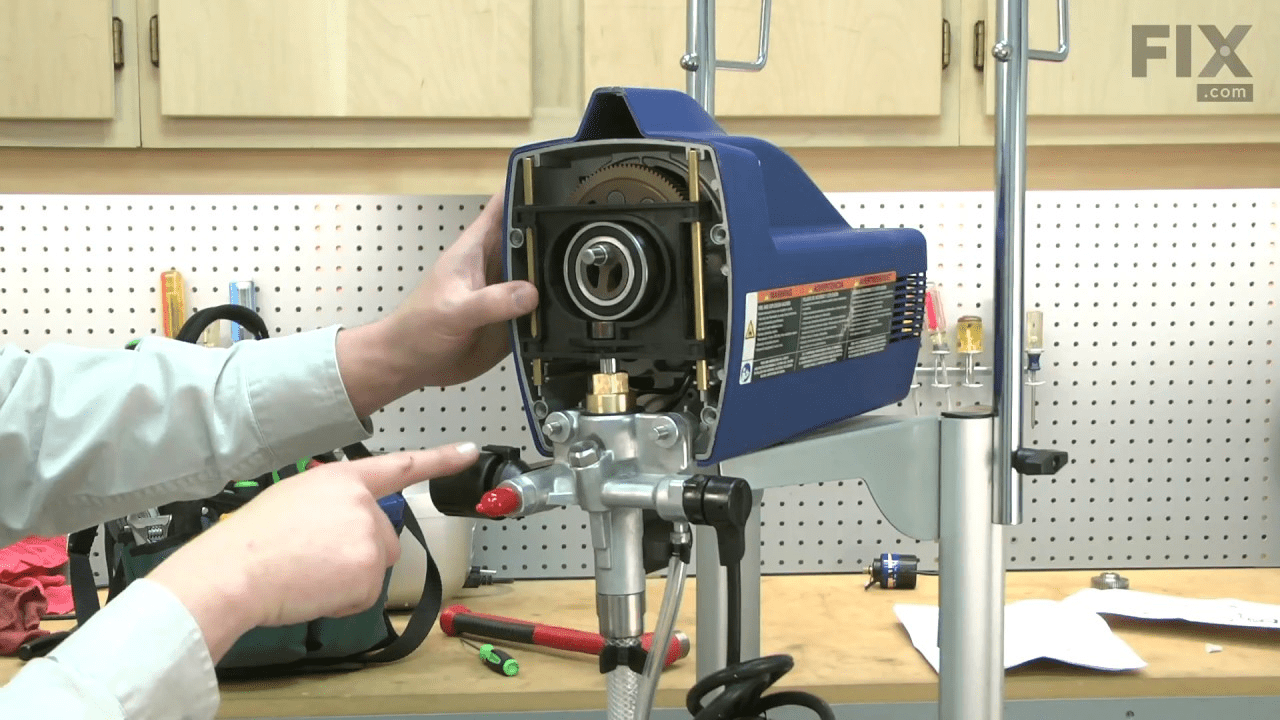

Drive Train Constituents

If your Graco sprayer has a drive train or motor, it’s crucial to check and maintain these parts. This includes the couplings, pulleys, and belts that make sure your sprayer runs smoothly.

Replacement Schedule

Depending on the model and usage, according to the manufacturer’s instructions for examining and replacing drive train parts.

Filters and Strainers for Fluids

Graco sprayers frequently include fluid filters and strainers placed throughout the system. These elements make sure that the coating material is of high quality and assist in preventing obstructions.

Replacement Schedule

To ensure optimal flow and avoid obstructions, regularly clean and inspect fluid filters and strainers, changing them as necessary.

O-Rings and Seals

Your Graco sprayer is filled with seals and O-rings, which are in charge of guarding against leaks and guaranteeing a tight seal in various parts.

Replacement schedule

To stop leaks and maintain performance, regularly check seals and O-rings for wear or damage and replace them as needed.

Conclusion

Keeping your Graco sprayer in good working order is crucial for getting consistent, excellent results from your painting and coating operations. You can increase the lifespan of your sprayer, decrease downtime, and guarantee the security of your operations. Long-term benefits include being able to continue taking advantage of efficiency and dependability.