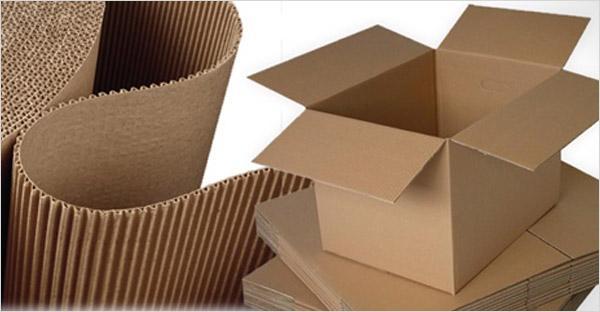

Corrugated cardboard is one of the primary materials that we use at cardboard boxes to make industrial packaging. This cardboard is one of the benefits of cardboard box since it is 100% recyclable and biodegradable.

Despite the fact that the packaging was first and foremost used to transport food from the manufacturer to the consumer, the fact remains that it has gradually been completed to the point where it is necessary for preserving almost all types of goods during transportation or for an extended period of time. Originally, the packaging was primarily used to transport food from the manufacturer to the consumer. However, the revolution in packaging has not yet come to an end, and as a result, the product is becoming more protected as it moves through the distribution chain.

One of the most common types of testing equipment used by those working in the packaging sector is the corrugated box. When it comes to keeping the material for a longer period of time, the quality of it is the factor that counts the most. The pressure will not cause the high-quality corrugated boxes to rupture quickly and they can sustain the pressure.

In what kinds of situations might a bursting strength tester be used?

One of the most precise measuring tools now on the market, the bursting strength tester digital model is produced by one of the companies that specialize in producing bursting strength testers. You will have no trouble calculating the bursting factor for either paper or corrugated boxes thanks to this tool’s unique two-in-one functionality. This testing equipment has been constructed in accordance with all of the industry requirements, and it has a digital LED display, which enables precise viewing of the results of the tests. This instrument meets all of the industry requirements and has a digital display. It has the unique ability to transmit results in a very short amount of time

When subjected to just a moderate amount of force or pressure, materials such as paper, cardboard, boxes, solid fiberboards, and other materials of a similar kind will quickly burst or rupture. You will be able to increase the quality, durability, and performance of the materials before you send them out to the clients by using the bursting strength test as a guide.

Measure the Burst Strength

The amount of force that may be exerted in a burst is measured in kilograms per square centimeter. The burst factor of a flexible or corrugated package is determined by taking into account both the burst strength and the grammage (density) of the material that makes up the package.

Benefits of bursting strength tester

It is advantageous to measure the bursting strength because it enables the Bursting strength tester manufacturers to evaluate the strength of the package and guarantee that it does not get destroyed while it is in transit. This is one of the main reasons why it is good to test the burstsing strength. You will be able to conduct an analysis of the qualities of your packaging material with the assistance of this testing tool. After you have analyzed various features, such as strength, durability, and so on, of the material you are using for your packing, your items will not be harmed while they are being transported. Because the packaging and the coatings on it may vary so much, you will need to refer to the standard that you wish to test to in order to determine what kinds of testing equipment are required.

When conducting burst strength testing, a force is applied to the fabric in order to determine the circumstances under which the box will break. Some important features are:

- Quality

The Bursting strength tester manufacturers keep the quality at an all-time high, without making any sacrifices in this regard.

- Reliability

The other word for dependability is the product’s packaging. You are able to depend on them one hundred percent.

- Durability

One of the Unique Selling Propositions (USPs) that the manufacturers have is the very long lifespan of their products.