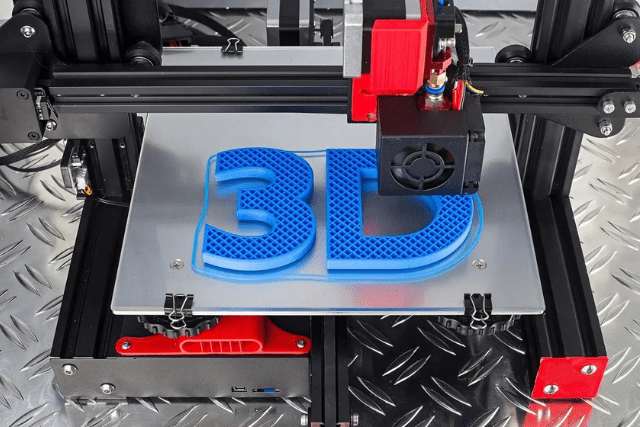

The manufacturing landscape has been revolutionized by the advent of 3D printing. This cutting-edge technology, also known as additive manufacturing, has emerged as a game-changer, unlocking a world of opportunities and advantages for various industries. In this comprehensive article, we will delve into the five key benefits of 3D printing in manufacturing. From streamlining production processes to enabling customized designs, this innovative technology offers a host of advantages that are reshaping the way products are created and manufactured.

1: Cost-Efficiency: Saving Time and Money

One of the most significant advantages of 3D printing in manufacturing is its cost-efficiency. Traditional manufacturing methods often involve expensive tooling and time-consuming processes. In contrast, 3D printing allows for rapid prototyping and production, reducing lead times and material wastage. Manufacturers can create intricate designs and functional prototypes without the need for specialized tools, resulting in significant cost savings. Additionally, the ability to manufacture on-demand eliminates the need for large-scale inventory storage, further reducing operational costs.

2: Design Freedom and Customization

With 3D printing, manufacturers can unleash their creativity and achieve unparalleled design freedom. From intricate lattice structures to organic shapes, 3D printing opens up new possibilities for designers and engineers. Moreover, 3D printing facilitates customization, allowing manufacturers to tailor products to individual customer needs without incurring additional costs.

3: Accelerating Innovation: Rapid Prototyping and Iteration

Innovation is at the core of 3D printing in manufacturing. The ability to rapidly prototype and iterate designs accelerates the product development cycle. Manufacturers can quickly test and refine their ideas, identify flaws, and make necessary adjustments without lengthy production delays. This iterative approach enhances the quality of the final product, as design flaws and weaknesses are identified and addressed early in the development process. As a result, 3D printing empowers manufacturers to stay ahead in a highly competitive market.

4: Lightweight and Strong Structures

3D printing allows for the creation of lightweight yet robust structures, offering significant advantages in various industries. By utilizing intricate lattice patterns and optimized geometries, manufacturers can reduce the overall weight of components without compromising on strength. In sectors like aerospace and automotive, this translates to improved fuel efficiency and performance. Additionally, the ability to consolidate multiple parts into a single 3D-printed component further enhances structural integrity and reduces assembly complexity.

5: Sustainable and Eco-Friendly Manufacturing

Sustainability is a critical concern in today’s manufacturing world. 3D printing aligns perfectly with eco-friendly practices by minimizing material waste. Traditional subtractive manufacturing methods often result in substantial leftover materials, but 3D printing adds material layer by layer, significantly reducing waste. Moreover, 3D printing enables the use of recycled materials, further promoting sustainability. By embracing this technology, manufacturers can contribute to a greener future while maintaining high-quality production.

FAQs (Frequently Asked Questions)

Q: Is 3D printing only suitable for rapid prototyping?

A: No, while 3D printing is indeed excellent for rapid prototyping, it has evolved to be a viable production method for various industries. From aerospace to healthcare, 3D printing is utilized in end-use part production, tooling, and even construction.

Q: What materials can be used in 3D printing for manufacturing?

A: 3D printing supports a wide range of materials, including plastics, metals, ceramics, and even food-grade substances. Each material offers unique properties, making 3D printing highly versatile for diverse applications.

Q: How does 3D printing impact the supply chain?

A: 3D printing can disrupt traditional supply chains by enabling decentralized manufacturing. Instead of relying on centralized production facilities, manufacturers can establish distributed manufacturing hubs, reducing transportation costs and lead times.

Q: Is 3D printing cost-effective for small-scale production?

A: Yes, 3D printing is particularly cost-effective for small-scale production runs. It eliminates the need for expensive tooling and allows manufacturers to produce small batches at a lower cost per unit.

Q: Can 3D printing be used for producing functional end-use parts?

A: Absolutely! 3D printing is now utilized to manufacture fully functional end-use parts that meet rigorous performance requirements. From automotive components to medical implants, 3D-printed parts are widely integrated into various products.

Conclusion

3D printing Services have revolutionized the manufacturing industry, offering a myriad of benefits that drive innovation, sustainability, and cost-efficiency. From accelerated product development to customized designs, this technology empowers manufacturers to remain competitive in an ever-evolving market. As we witness continuous advancements in 3D printing, its impact on manufacturing will only grow stronger, shaping a more efficient and sustainable future.