A ball mill and a pin mill are both types of grinding mills that are used to grind and blend materials.

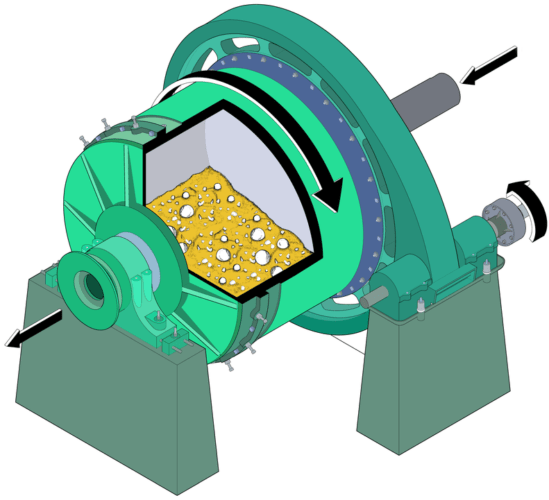

A ball mill is a type of grinder that is used to grind and blend materials for use in mineral processing, ceramics, and other industries. It works by rotating a cylinder filled with grinding media such as steel or ceramic balls, which collide with the material being ground to create a fine powder. Ball mills can be used for both wet and dry grinding.

A pin mill, on the other hand, is a type of grinder that uses a series of rotating pins or blades to grind materials. The pins or blades are arranged in a vertical or horizontal rotating shaft, which causes the material to be ground between the pins or blades and the stationary grinding surface. Pin mills are often used for fine grinding and deagglomeration of materials, and they are commonly used in the food, chemical, and pharmaceutical industries.

While both ball mills and pin mills are used for grinding and milling materials, they have different mechanisms of operation and are better suited for different applications. Ball mills are typically used for large-scale production of materials, while pin mills are commonly used for small-scale and laboratory applications, as well as for fine grinding and deagglomeration of materials.

A ball mill is a type of grinding equipment used to grind materials into fine powder. It consists of a hollow cylindrical shell that rotates about its axis. The shell is generally filled with balls made of metal or ceramic that are used to crush and grind the material being processed.

There are several factors to consider when choosing a Ball Mill Manufacturer India, including the following:

- Quality: Look for a manufacturer that uses high-quality materials to construct their ball mills. The materials used can affect the longevity of the machine and the quality of the products it produces.

- Performance: Consider the capacity, speed, and efficiency of the ball mill. The manufacturer should be able to provide specifications that demonstrate the performance of the machine.

- Cost: The cost of a ball mill can vary depending on the size, materials used, and other factors.

- Customer Service: A good manufacturer should provide excellent customer service, including technical support, maintenance and repair services, and responsive communication.

Read reviews and testimonials from other customers to determine their satisfaction with the company and its products.

When choosing a ball mill manufacturer, it’s important to evaluate your specific needs and goals. Consider the type of material you’ll be processing, the desired particle size, and the quantity of material you’ll be processing. This will help you choose the right type and size of ball mill for your application.

Overall, a ball mill can be an effective tool for grinding and processing a variety of materials. By choosing the right manufacturer and machine, you can maximize the performance and efficiency of your production processes.

Ball mills are versatile machines used in a wide range of industries for various applications. Here are some common uses of ball mills:

- Grinding and mixing: The primary function of a ball mill is to grind and mix materials to produce a fine powder. This is done by using a series of balls in a rotating cylindrical shell. The grinding action crushes the material into small particles, and the mixing action ensures that the particles are evenly distributed.

- Material refinement: Ball mills are commonly used to refine materials, such as metals and ceramics, to improve their properties. For example, a ball mill can be used to refine the grain structure of metal alloys, making them stronger and more durable.

- Size reduction: Ball mills can be used to reduce the size of particles in a material, such as in the case of reducing the size of ores for subsequent processing.

- Mechanical alloying: Ball mills are commonly used in the process of mechanical alloying, where different materials are mixed together and subjected to high-energy collisions to form alloys with unique properties.

- Pharmaceutical industry: Ball mills are used in the pharmaceutical industry to grind and mix medications and other compounds. This helps to ensure consistent particle size and distribution, which is critical for ensuring the effectiveness of the medication.

- Cement production: Ball mills are used in the cement industry to grind and mix raw materials to produce cement. The grinding action crushes the raw materials into a fine powder, which is then mixed with water and other additives to produce cement.

- Food industry: Ball mills are also used in the food industry to grind and mix ingredients to produce products such as chocolate, confectionery items, and spices.

Pin mills are versatile machines that are used in a wide range of industries for various applications. Here are some common uses of pin mills:

- Grinding: The primary function of a pin mill is to grind materials to produce a fine powder. This is done by using a series of pins in a rotating rotor that creates high-speed impact with the material being processed. The grinding action crushes the material into small particles, resulting in a fine powder.

- Size reduction: Pin mills are commonly used to reduce the size of particles in a material. They are often used in the food industry to reduce the size of spices, grains, and other ingredients.

- Deagglomeration: Pin mills can be used to deagglomerate material that has become clumped or stuck together. This is important for industries such as the pharmaceutical and chemical industries, where it is necessary to break up material that has clumped together during storage or transportation.

- Mixing: Pin mills can be used to mix different materials together to produce a homogeneous mixture. This is useful in the food and chemical industries, where it is important to ensure that the ingredients are evenly distributed.

- Particle size control: Pin mills can be used to control the particle size of a material. This is important in industries such as the pharmaceutical industry, where it is necessary to ensure that the particles are a consistent size for effective delivery.

- Cosmetic industry: Pin mills are used in the cosmetic industry to grind and mix ingredients to produce products such as face powders, eye shadows, and lipsticks.

- Chemical industry: Pin mills are used in the chemical industry to grind and mix chemicals to produce products such as pigments, dyes, and inks.

In conclusion, when it comes to selecting the right equipment for your grinding needs, it is essential to consider the characteristics of both pin mills and ball mills. Pin mills are highly versatile machines that can produce fine to coarse particles, making them suitable for a wide range of applications. On the other hand, ball mills are more efficient and can produce finer particles, making them ideal for grinding materials that require a high degree of precision.