In this post, we will talk about how does the process pump control system operates? So to know, read this article till the end.

When it comes to processing control, it is the capacity to modify or manage activity on a regular basis in order to achieve predictable desired results. In the context of pumping, this refers to the process of regulating a pump such that it produces the required flow and/or pressure outcomes in the system in which it operates. Most of the time, this implies that information about the system environment is sent to the pump, allowing it to automatically modify its operation in order to appropriately meet the needs of the current scenario.

Process control is widely employed in industry, and it allows for the mass production of continuous processes in a variety of sectors, including oil refining, paper manufacture, chemical formulation, electric power generation, and a variety of others. Because of process control’s ability to automate, a small team of operational people may run a complicated process from a centralized control room.

When automating fluid handling operations, it is important to verify that you are utilizing the most appropriate kind of pump for the process at hand, as well as understanding how to regulate the type of pump that is being used. The two main types of process pumps, centrifugal and rotary positive displacement require control methods that are totally distinct from one another. The limits of each pump type must be understood, and when creating new processes, it is especially essential to understand which kinds are the most controllable in order to reduce scaleup risks from the laboratory to the pilot and, eventually to the commercial scale.

The process pump is a centrifugal pump that is used in chemical processes, such as those found in oil refineries and the petrochemical sector, among other places (see Refinery pump). Its design is often of the pull-out kind from the rear. A process pump is similar to a chemical pump in that they are used to handle strong chemical fluids. Aside from that, they are suited for systems with high system pressures and temperatures. For example, a process pump could be utilized in the oil sector.

In what way does Process Pump Control serve a purpose?

The controller regulates the speed of the pump and, as a result, the output of the pump. A variety of sensors, such as flow meters and level sensors, provide the input variables. After that, the information activates the pump controller, which subsequently changes the speed of the pump to the optimum setting for the given situation. Pumps may be controlled in a straightforward manner via the use of inverters, converters, or frequency inverters.

The rotational speed may be changed by varying the amplitude or altering the frequency of the rotating motor. With the help of an inverter, the control system can be operated extremely efficiently and rapidly, which is reflected in the excellent controllability of the pumping plants once again.

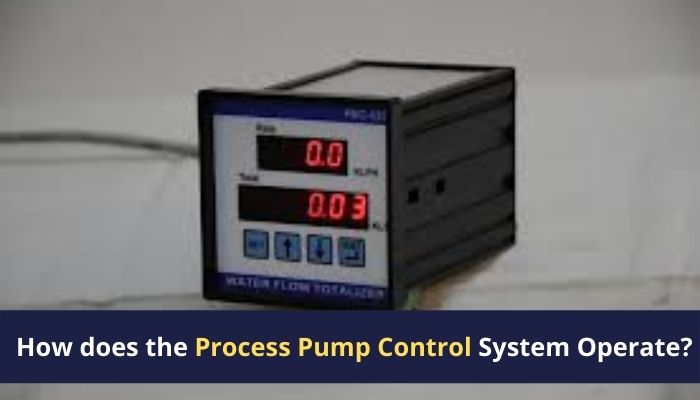

What is the procedure for operating the Process Pump Control System?

The automated water Process Pump Control System automates the starting and stopping operations of the water pump in response to a reduction in pressure (by opening the taps) and a reduction in flow through the system (by shutting the taps), as appropriate.

It guarantees that the water pressure remains consistent while you are using the faucet. You won’t have to worry about experiencing the dreaded “pressure drop” while you are in the midst of washing your hair, watering your lawn, or hosing down a work area since it will rapidly increase the water pressure.

When there is a lack of water supply, the controller will shut down the pump, preventing the pump from becoming inoperable and resulting in damage.

The Automatic Pressure Control system works as follows: Water pump discharge is connected to a switch that works with an electronic circuit board to detect pressure and flow in a closed-loop water system. Fits the vast majority of conventional water pumps.

This is how a process pump control system operates. I hope you enjoyed this article.