Industrial metal surfaces degrade quietly. Oxidation builds, coatings fail, and productivity slows. Traditional cleaning methods remove rust-but they also remove time, precision, and surface integrity. Manufacturing teams now seek controlled, low-impact solutions that align with automation and sustainability goals. Everyone wants to evaluate emerging systems that reduce waste while improving operational consistency. This shift explains the growing interest in the hand-held Laser rust remover, a tool redefining how metal cleaning has been approached and standardized across technical environments.

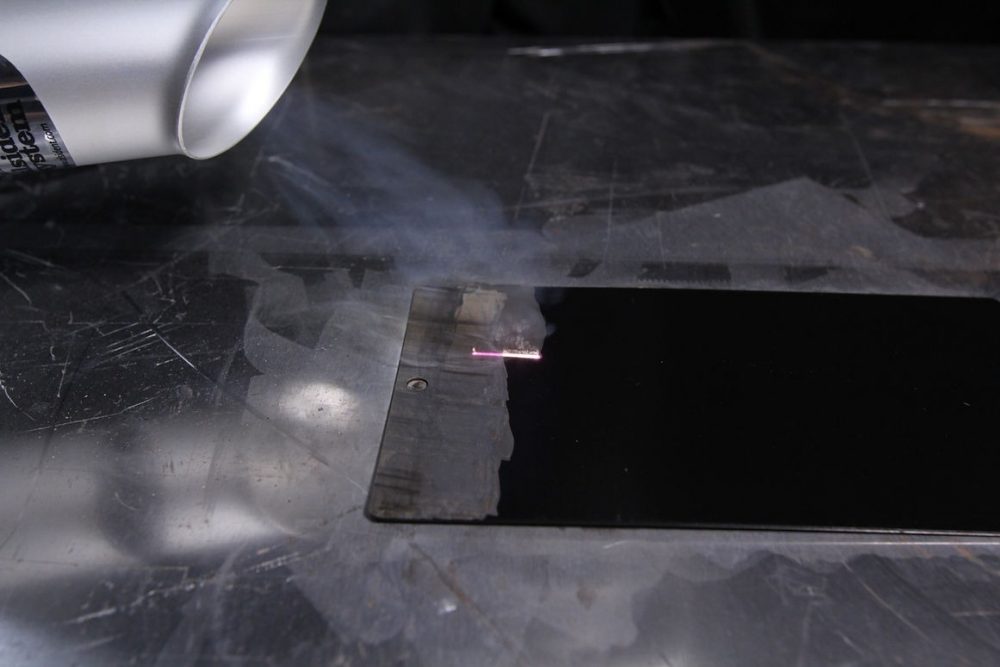

The Science Behind Rust Removal Based on Laser

Laser cleaning works through focused photothermal interaction. High-energy laser pulses strike oxidized layers and contaminants to absorb energy and disintegrate. The base metal reflects most of the wavelength, preventing substrate damage. This selective interaction ensures accuracy at a micron level. Unlike abrasive techniques, no mechanical friction occurs. The process remains dry, controlled, and repeatable, making it suitable for precision-driven workflows and sensitive metal assemblies where tolerance margins are tight.

Precision Without Surface Loss

Metal components often fail not from rust alone, but from over-cleaning. Grinding, blasting, or chemicals remove usable material along with corrosion. Laser surface cleaningavoids this problem by isolating oxidation layers only. Surface roughness stays within design specifications. Dimensional accuracy remains stable. Over time, this precision extends component lifespan and reduces rework cycles. For facilities managing high-value metal parts, controlled material retention directly supports quality assurance and long-term cost control.

Operational Efficiency in Compact Form

Mobility matters in modern facilities. Handheld laser systems allow operators to move between stations without dismantling equipment. Setup time remains minimal. Calibration is digital, not manual. Workflows improve because cleaning occurs in-place rather than off-site. Energy usage remains steady, and frequently even lower than that of pneumatic or chemical systems. A prolonged application of this efficiency leads to obvious decreases in the aforementioned areas—downtime, labor intensity, and operational bottlenecks—along with cost savings.

Cleaner Processes With Lower Environmental Impact

Environmental compliance increasingly shapes industrial decisions. The chemical rust removal process generates runoff, a hazardous issue. Sandblasting spreads dust and other particulates. Laser oxide removaleliminates both. No secondary waste forms. No solvents enter disposal streams. Air quality remains stable. This aligns with stricter internal safety protocols and evolving environmental standards. Facilities adopting laser-based cleaning often reduce regulatory overhead while improving worker safety conditions, an advantage that compounds over time.

Consistency Across Tasks that are Repetitive

Manual cleaning depends heavily on operator skill. Results vary. Laser systems rely on programmable parameters instead. Power, frequency, and scanning speed remain consistent across sessions. This repeatability ensures uniform surface preparation, especially before coating, welding, or bonding. Consistent surfaces improve downstream adhesion rates and reduce defect frequency. Over production cycles, this consistency supports predictable output quality and tighter process control metrics.

Reduced Maintenance and Tool Wear

Traditional tools degrade quickly. Brushes wear. Blasting nozzles clog. Chemical baths lose potency. Laser systems experience minimal physical wear because no contact occurs with the surface. Maintenance schedules lengthen. Consumable costs drop. Over long-term deployment, ownership costs stabilize. For operations managing multiple cleaning stations, reduced tool replacement simplifies inventory planning and budgeting cycles.

Safety Advantages for Operators

Worker safety improves through indirect benefits. No sharp debris rebounds. No chemical exposure occurs. Noise levels remain lower than those of blasting systems. Operators maintain better visibility and control during cleaning. Training focuses on system settings rather than physical force. These factors reduce fatigue and accident risk, especially during extended shifts. A safer process encourages consistent performance without sacrificing throughput.

Adaptability Across Metal Types

Different oxides of metals are formed differently. Steel, aluminum, and their alloys, for instance, have different reactions to corrosion. The laser systems come with adjustable parameters that reflect the same thermal behavior. This adaptability allows one system to service multiple material categories. Facilities avoid maintaining separate cleaning methods for each metal type. Standardization improves efficiency and simplifies operator training across departments.

Long-Term Value Beyond Initial Investment

Initial costs often raise questions. However, lifecycle analysis tells a different story. The wholelaser surface cleaning, together with reduced consumables, lower waste handling, fewer defects, and faster turnaround, has its upfront investment offset. Gradually, laser cleaning is no longer an expense but a cost-stabilizing asset. When incorporated into preventive maintenance schemes, it adds measurable value to the resilience of the operation.

Why Trends Focuses on This Technology

Every industry prioritizes solutions that combine technical accuracy with operational practicality. Laser cleaning systems meet both criteria. They simplify complex workflows while maintaining engineering precision. This balance explains why industries are steadily shifting toward laser-based rust removal as a foundational maintenance process rather than a niche solution.

Conclusion: Rethinking Rust Removal at the Source

Degradation of metals is a process that can’t be stopped completely, but the way it is handled may still be improved. Cleanliness methods are characterized now by accuracy, uniformity and regulation of the atmosphere. The Hand-held Laser rust remover represents this shift by offering controlled performance without material compromise. A good industry solution continues to support technologies that align efficiency with sustainability, ensuring metal assets remain functional, reliable, and production-ready for extended operational cycles.