CNC PCB are an essential part of many electronic devices, including computers, mobile phones, and other gadgets. While PCBs themselves are typically made with a lot of parts, they can be made easier by using a CNC machine. This article breaks down the steps for making PCBs on a CNC machine and how to make your own PCB at home!

What is a PCB?

A CNC PCB is an acronym for “printed circuit board.” A PCB is the basis of many electronic devices, including computers, printers, and mobile phones. PCBs are created when layers of copper are soldered onto a board with wires running between the parts.

How can you make PCBs?

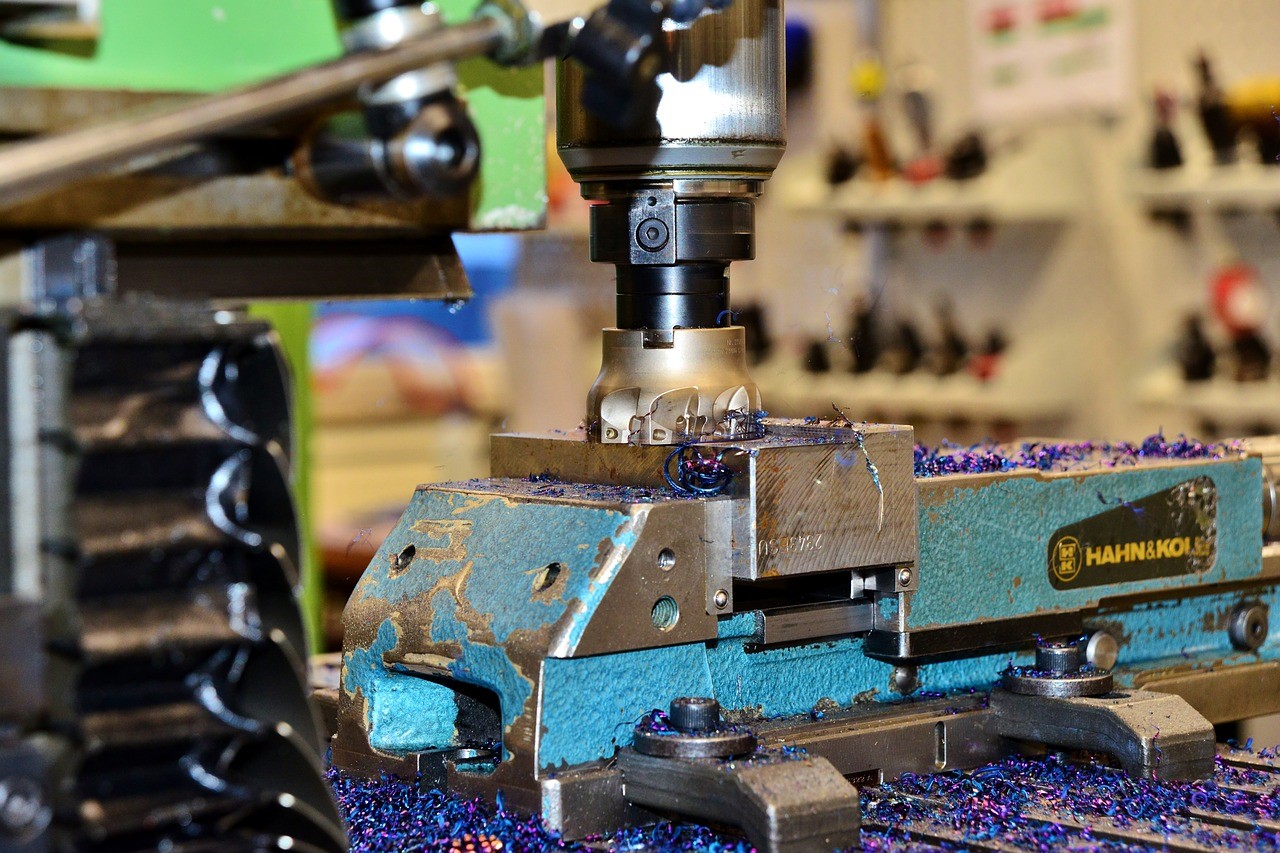

PCBs are PCBs (Printed Circuit Boards). But how can you make them? By using a CNC machine to cut the board from a sheet of copper, lead, or other conductive material, You can also use a laser cutter or plotter for this purpose.

PCB Advantages and Disadvantages

The process of PCB fabrication is not the same for every company, but it is similar. PCB fabrication can be an expensive process for many companies. However, there are many benefits associated with PCBs. One benefit of this technology is that it enables anyone to test their circuit board without having to use any sophisticated equipment. Circuit boards are also durable and may last for years depending on the amount of use you get out of them. The disadvantages of PCBs One potential problem associated with PCB fabrication are that it can be an expensive process. You will need a number of specialized tools to perform PCB fabrication.

Safety Tips for PCBs

PCBs are a good way to create your own projects. They can be used for a variety of purposes, from home decor to small electronic devices. The most important aspect of PCB manufacturing is safety. To ensure safety when manufacturing PCBs, you must follow these tips:

1) Maintain a clean work environment.

2) Place all materials used during the process in their proper place.

3) When working with PCBs, always wear protective clothing.

4) Make use of an inspected PCB fabrication machine.

Why are PCBs Used in CNC Machine Parts?

PCBs are generally mixed in with the rest of the metal that is used in CNC machine parts to create a finished product. They are generally created by mixing different metals together and then heating them up enough for them to fuse together. This gives the part its desired properties, such as strength and thermal conductivity.

How to Make Your Own PCBs on a CNC Machine

PCBs are a vital part of any electronic project, and luckily, they’re also very easy to make. If you’re just getting started with PCBs, this is the perfect blog to follow. This blog will show you how to build your own PCBs on CNC machine parts and will provide step-by-step instructions for anything you might want to make. PCBs are difficult to make this way, but they can be made quickly and easily with the help of a CNC machine. PCBs can be produced without a design or the help of a hardware engineer. Small PCBs can be made from hand-held cutting tools, but larger boards need special dedicated machines that use computer numerical control (CNC) to produce the boards.